Reciprocating Pumps Trouble Shooting Guide

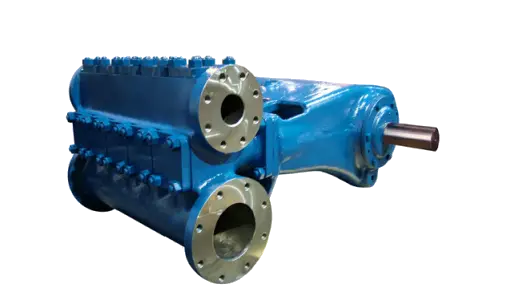

Servicing all Wheatley Duplex, Triplex, Quintuplex Plunger and Piston Pumps.

- Air or vapor pocket in inlet line

- Capacity of charge pump less than capacity of power pump

- Air or vapor trapped in or above inlet manifold

- Air leak in liquid supply piping system

- Loose bolts in pump inlet manifold

- Air or gases entrained in liquid

- Foreign object holding pump inlet or discharge valve(s) open

- Incorrect drive ratio

- Loose belts

- Incorrect motor or engine speed

- Loose valve covers or cylinder head

- Worn valves and seats

- Safety relief valve partially open, or not holding pressure

- Worn liners, piston rings or plungers

- Bypass valve open, or not holding pressure

- Blown liner gasket

- NPSHA not sufficient

- Liquid bypassing internally

- Foreign object blocking liquid passage

- Vortex in supply tank

- Insufficient power delivered by motor

- Inlet line partially clogged

- Liquid vapor pressure too high

- Liquid pumping temperature too high

- Restricted inlet pipe fittings

- Inlet line too long

- Too many pipe fittings

- Too small inlet line

- Too low static inlet head

- Too low atmospheric pressure

- Pump not primed

- Air or vapor pocket in inlet line

- Clogged inlet line

- All inlet valves propped open

- All discharge valves propped open

- Loose bolts in pump inlet manifold

- Too high valve velocities

- NPSHA too low

- Liquid NOT Delivered to Pump Inlet Connection

- Excessive Stuffing Box Leakage

- NPSHR too high

- Over Recommended Pressure

- Loose Cylinder Head/Valve Cover

- Damaged Gasket/O-ring

- Water Condensation

- Worn seals

- Clogged Air Breather(s)

- Worn Crankcase Packing

- Loose Covers

- Oil Level/Temperature Too High

- Worn seals

- Worn Crankcase Packing

- Loose Crankcase Cover

- Pump Running Backward/RPM too low

- Insufficient Oil in Power End

- Excessive Oil in Power End

- Incorrect Oil Viscosity

- Operating Pump above Recommended Pressure 6) Main Bearings too Tight

- Drive Misaligned

- Belts too Tight

- Discharge Valve, one or more, Stuck Open 10) Insufficient Cooling

- Pump RPM too Low

- Inadequate Ventilation

- Liquid End Packing Adjusted too Tight (adjustable style packing only)

- Pump RPM too High

- Low Voltage or other Electrical Trouble

- Trouble with Engine, Turbine, Gear Reducer or other Related Equipment

- Excessive Discharge Line Pressure

- Clogged Discharge Line

- Closed/Throttled Valve in Discharge Line

- Incorrect Plunger/Piston Size for Application

- Improper Bypass Conditions

- Over-tightened Stuffing Box Glands on Adjustable Packing

- Worn Packing

- Worn rods or plunger

- Worn stuffing boxes

- Wrong size packing

- Worn O-ring seal (replaceable boxes)

- Excessive discharge pressure

- Improper torquing of nuts

- Shock overload caused by pump cavitation

- Broken or weak valve spring

- Pump cavitation

- Air leak in inlet piping or loose bolts in pump inlet manifold

- Air trapped above inlet valve

- Piping inadequately supported

- Inlet line too long or too small in diameter

- Too many bends in inlet line

- Multiple pump installations operating in phase

- Obstruction Under Valve(s)

- Packing Worn

- Operating Above Recommended Pressure or RPM 8) Low NPSHA

*Be sure to differentiate between liquid knock and mechanical knock – very few knocks are mechanical on new installations.

- Piston or plunger loose

- Valve noise amplified through power end

- Pump cavitation

- Liquid knock

- Air leak in inlet piping

- Loose bolts in pump inlet manifold

- Hydraulic noise in liquid end

- Loose or worn crosshead pins and bushings

- Loose connecting rod cap bolt

- Worn connecting rod bearings

- Worn crosshead

- Main bearing end play excessive

- Worn gears or chains

- Gears or chains out of line

- Pump running backward

- Partial loss of prime

- Shocks in piping system

- Water in power end crankcase

- Poorly supported piping, abrupt turns in piping, piping misaligned, pipe size too small